Waffle weave

If you haven’t tried waffle weave yet – you will be amazed at the magic that happens when you take it off the loom and wash it. Stefan Moberg wove these beautiful cotton towels that featured in Issue 33 of The Wheel magazine. These were woven on the Jack loom and the draft is a tie-up. I have also included a lift plan draft for a scrumptious woollen throw woven on a 60cm eight shaft table loom.

Happy weaving!

Kate

WAFFLE WEAVE TOWELS

Wrap yourself in luxurious, three-dimensional, hand woven waffle weave towels. By Stefan Moberg

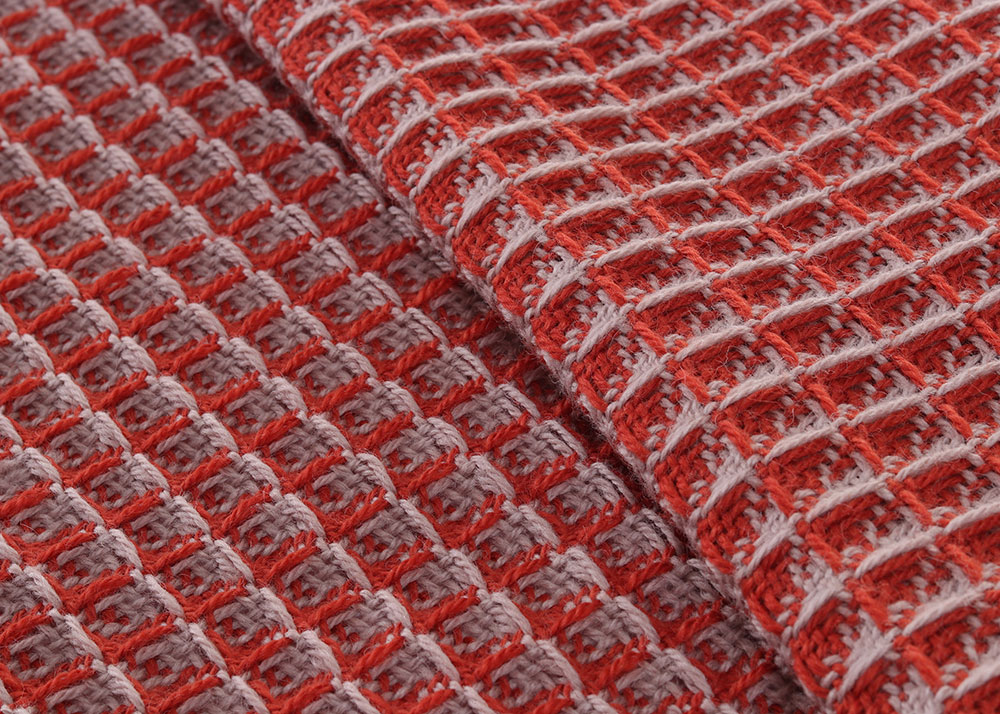

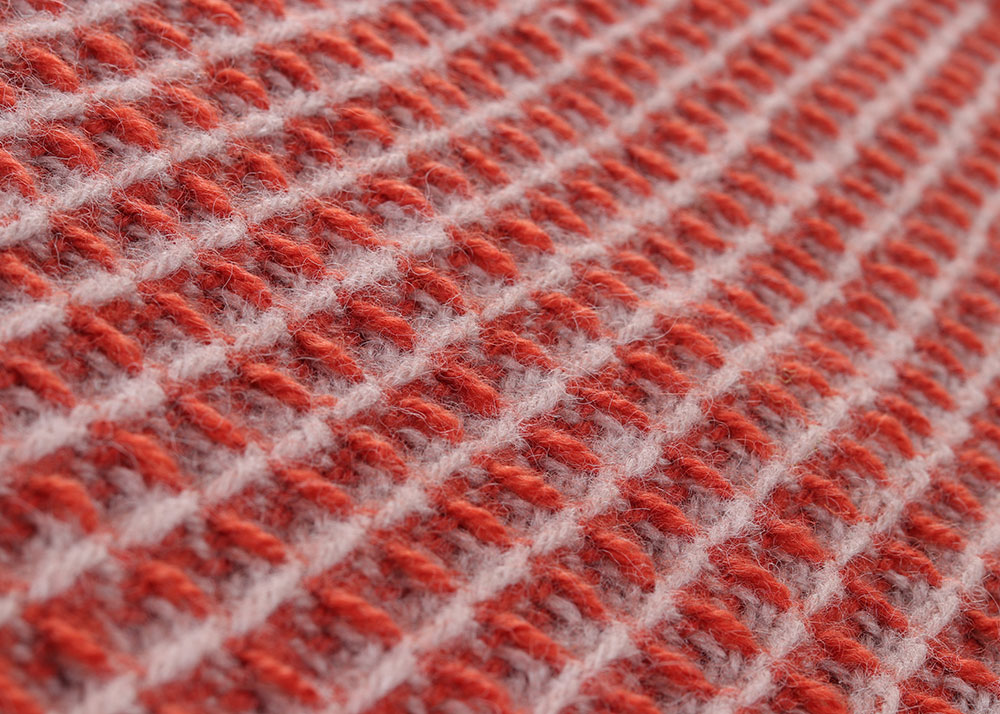

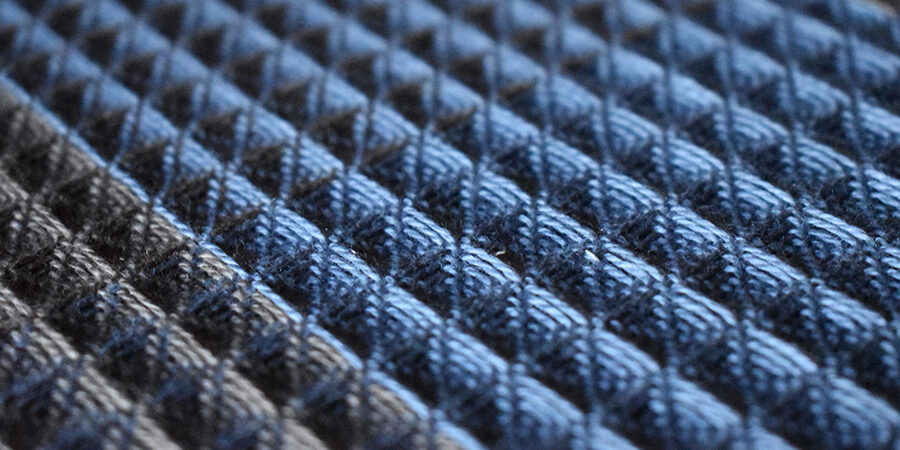

Waffle weave is made up from the difference between the tight nature of plain weave and progressively longer (and shorter) floats. These are arranged in a diamond-like manner and when the fabric comes off the loom the long warp and weft floats will pull the fabric together at the same time as the plain weave areas will try and hold their ground. This effect causes ridges and depressions to form and when studying the fabric closer you will see squares with a three-dimensional indentation in the middle, which are called “cells”.

Waffle weave is a very classic technique for hand woven towels, producing a thick and absorbent fabric. This technique is one of those that sport a rather dramatic change in the finishing process. When the textile is kept under tension on the loom it all stays pretty flat, but once you take it off the loom and wash it, something magical happens – the fabric goes full-on three-dimensional! It’s an alluring process and washing a waffle weave towel is a very exciting thing!

A note on yarn: There are amongst hand weavers rather a lot of opinions on using mercerised or unmercerised cotton yarns for towels. Some will say that mercerised yarns won’t absorb water as well as unmercerised yarns, and others will say the exact opposite. There are studies on this, for the weaver who would like to dive into the scientific side of things. In my experience in weaving towels for the home, I haven’t noticed a dramatic enough difference between the two to be able to say with certainty that it’s one way or the other. Having said that, I have mostly used unmercerised yarns for towels, since I much prefer the matte surface of them to the shiny look of a mercerised yarn when it comes to everyday household textiles. This is, of course, up to you as the weaver – you can make the choice yourself!

BATH TOWELS

You will need:

Loom: 97cm (38ins) 8 shaft loom or wider

Reed: 12dpi reed (sleyed 1,2) or 8dpi reed (sleyed 2-2-2-3)

Warp: Ashford unmercerised cotton Ne 5/2, 08 Pine Bark and 10 Twilight grey

Weft: Ashford unmercerised cotton Ne 5/2, 08 Pine Bark and 10 Twilight grey

Other: 100% cotton sewing thread for weaving the hem

Amount of yarn needed: 4 cones of each colour = total 8 cones for two bath towels

Here’s how:

Width in reed: 97cm(38ins)

Sett: 18epi

Weft sett: 7 picks per cm (18ppi)

Number of ends: 680 (340 in colour 08 and 340 in colour 10)

Warp length: 5.1m (5 ½yds)

Finished measurements: 75 x 175cm (30 x 70ins)

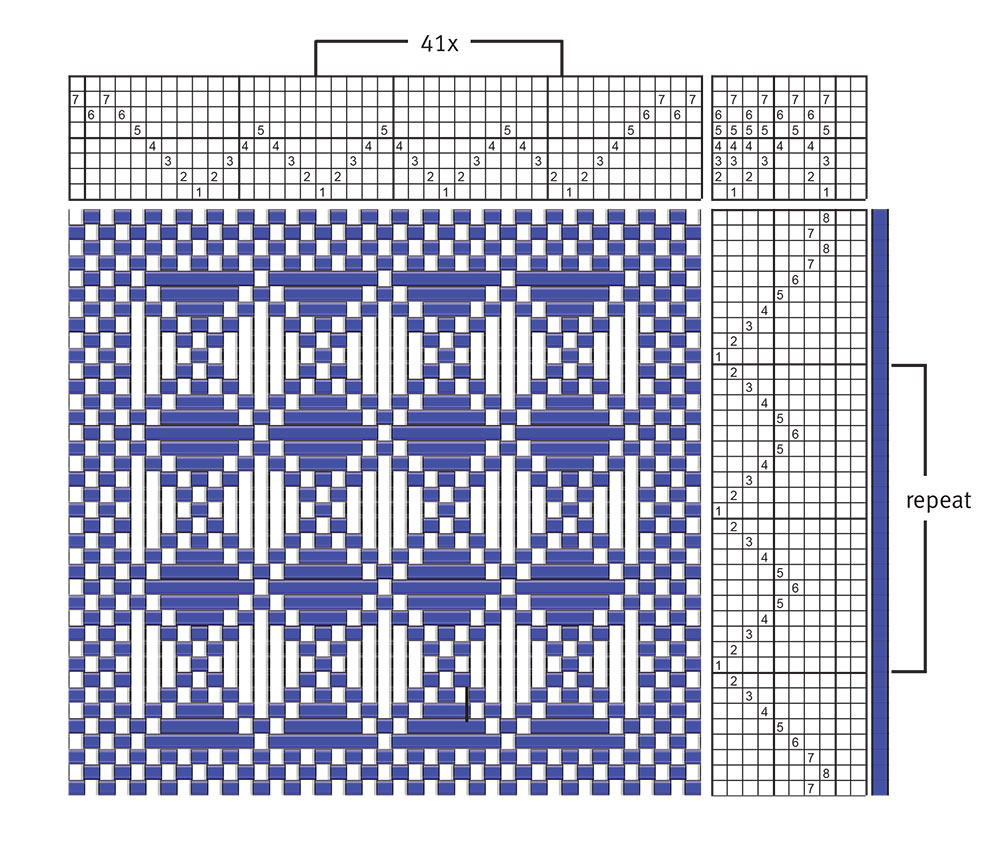

Weave structure

Waffle weave, 5 shafts and 6 pedals PLUS plain weave (for hem and selvedge edge), 2 shafts and 2 pedals = 7 shafts and 8 pedals

Warping

Wind warp and thread as per the draft.

Weaving

Weave the hem using 100% cotton sewing thread for weft. This will produce a lighter hem which won’t wrinkle so much when washing the towels (this happens due to the waffle weave’s great will to shrink and the plain weave hem’s tendency to not shrink so much).

1. Weave a 3cm (1 ¼ins) hem using sewing thread as weft.

2. Using the 5/2 cotton, colour 08, weave 10cm (4ins) of waffle weave.

3. Switch to colour 10 and weave 10cm (4ins).

4. Repeat the 10cm stripes a total of 20 times, a total of 200cm (80ins) per towel.

5. End the towel with a 3cm (1¼ins) hem, using sewing thread as weft.

6. On the loom, separate the two towels with a few picks of a scrap yarn in a contrasting colour in between the two hems. This will help you when cutting them apart when you’re done weaving.

7. Repeat for the second towel.

Finishing

After you’ve cut the weaving off the loom, cut the towels apart and hem at each end. Fold the hem twice on itself and sew using a machine or by hand. Wash the towels as you would any towel. I like to run them on a 60°C (140°F) programme in the washing machine.

When working with waffle weave it’s good to be aware of the fact that the structure shrinks a lot when you wash it for the first time. Please take this into consideration when designing your own. Weaving a sample is always a good idea!

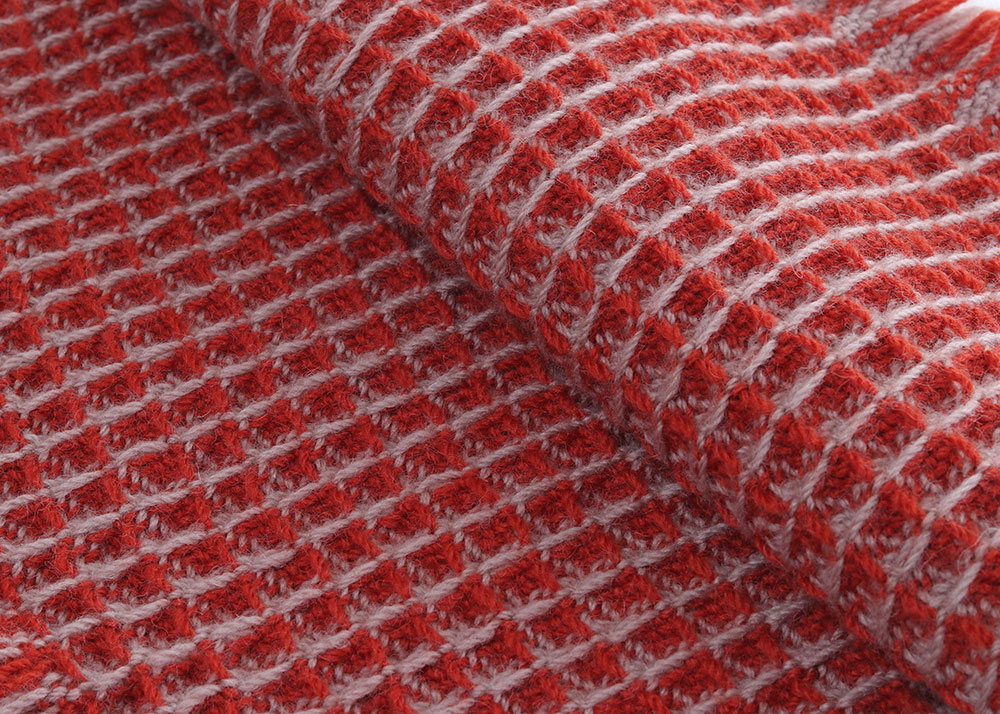

ASHFORD DK WOOL THROW

You will need:

Loom: 60cm (24ins) 8 shaft loom or wider

Reed: 10dpi reed

Warp: Ashford DK, 100% Wool, in two colours, one light and one dark – 100gm balls.

Weft: Ashford DK, 100% Wool, in the same two colours as warp – 100gm balls.

Amount of yarn needed: This will depend on the length you are weaving. For a finished (washed) throw 1.80m x 50cm you will need 3 balls of each colour.

Here’s how:

Width in reed: 60cm(24ins)

Sett: 10epi

Weft sett: 4 picks per cm (10ppi)

Number of ends: 234

Warp length: 2.25m (2.4yds)

Finished measurements: 50cm x 180cm (20 x 70ins)

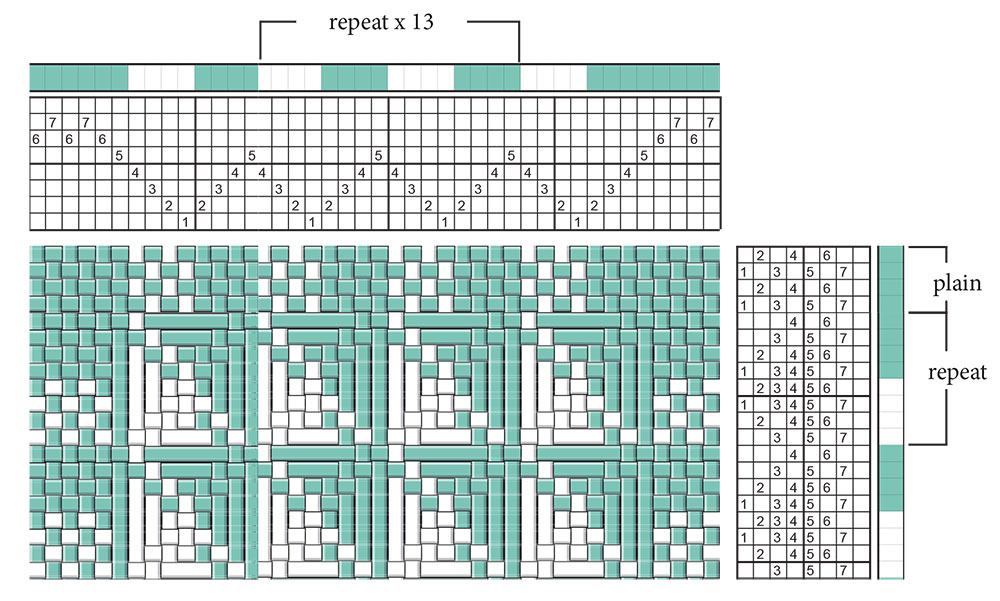

Weave structure

Waffle weave, 5 shafts PLUS plain weave (for hem and selvedge edge), 2 shafts – min. of 7 shafts required. There is no need for floating selvedges as there is a border of plain weave on each side.

Warping

Wind warp and thread as per the draft.

Weaving

Weave 2cm in plain weave, hemstitch then weave as per draft. You will be weaving 4 picks of the dark colour followed by 4 picks of the light. Wrap one shuttle around the yarn from the previous colour to “carry” the colour not being used up the edge of the weaving neatly.

Finishing

After you’ve cut the weaving off the loom trim fringe to preferred length. Or you can hem by folding the plain weave twice on itself and sew using a machine or by hand. Soak in hot water for 30 minutes with no agitation, then place in washing machine on gentle wool wash or wash and agitate by hand until the fabric is fulled to your liking. Dry flat. Enjoy your super squishy throw!