In 1934 Walter Ashford founded Ashford Handicrafts Ltd, a company that has become a world leader in the manufacture of quality spinning wheels, weaving looms and textile equipment.

Today the company and their loyal team, have produced over 900,000 wheels and looms.

The finest Beech hardwood, sourced from sustainably managed forests with Forest Stewardship Council approval, is used.

The Ashford wheels, looms and carders are the result of more than 90 years’ experience, customer feedback, research and development. The products are available in natural wood or finished with eco-friendly water-based lacquer. They are designed to be simple, easy to assemble and finish and fun to use.

At their woollen mill in Milton, New Zealand, high quality fleeces and fibres are sourced and transformed into beautiful colours and sumptuous blends.

Experience the joy and pleasure of creating your own unique yarns, fabric, garments, and homeware using Ashford wheels, carders, looms, fibres, and yarns. Relax knowing your crafts are sustainable, renewable, and environmentally friendly.

We invite you to join the Ashford family of textile artists around the world.

– Elizabeth, Richard and James Ashford and David Lester

History

It all began with a young man in the right place at the right time. The worldwide depression of the 1930s was not Walter Ashford’s idea of a good time for starting a business, but with purpose and determination he converted the family laundry into a tiny workshop in one of the most depressed suburbs in Christchurch, New Zealand.

Four days a week he worked making wooden fireside stools with woven seagrass seats. On the fifth day, with a stool on the handlebars of his bicycle, he rode the city knocking on doors and learned first-hand that quality and value resulted in orders.

‘Assemble and save’

Not long after this the Ashford family moved to Rakaia, a small country town. Here Walter set up a small factory. He repaired furniture and began making everything from picture frames to chicken coops. Good workmanship and modest prices brought their own reward. However, Rakaia’s population of only nine hundred was hardly enough for potential growth. What he needed were more customers. So, he decided to sell his fireside stools by mail order. Wrapping up stools and posting them presented him with a second problem, the matter of size. Then Walter had his second bright idea. He would make the wooden parts for the stools and post them together with the seagrass and an instruction sheet for customers to ‘Assemble and Save’, a catch phrase that became the company’s slogan.

As a result Ashford kitsets became a great success on the New Zealand scene. Because Walter was a practical man with a flair for design, his staff and production line expanded to include nursery and household furniture, utilities, and toys. Walter’s greatest assets were his ability to design simple practical products and the specialised machinery to make them.

The spinning revolution

In 1940 the Home Journal magazine asked Walter to design a spinning wheel that could make knitting yarn. It had to be aesthetically pleasing, functional, robust, trouble-free and yet a simple kitset that could be posted all over New Zealand. The first spinning wheel was a double drive model, but Walter soon discovered that spinners wanted to change the bobbins with ease. So, with the help of his father, the Reverend Dudley Ashford, the Ashford Scotch Tension flyer was developed and a patent pending awarded for its unique design. This revolutionary idea enabled the drive belt to be left on the flyer and it was just a simple matter of releasing the Scotch Tension to remove the bobbin. Today this innovation has become the industry standard.

During World War 2, Walter’s wheels were in great demand in New Zealand to create yarn for woollen socks and clothes for our soldiers, sailors, and airmen overseas. While Walter served in the Airforce, his father managed the business and with the help of a disabled foreman and a team of women, kept the factory working at top speed to produce over 3,600 spinning wheels.

In 1945 Walter returned to his factory only to find that nylon, the new wonder fibre, was overtaking wool and the need for hand spinning. For the next 20 years hand spinning slumbered like Sleeping Beauty.

Interest in wool revived

Then one day in 1965 Pamela Simcox knocked on the factory door and said, “Please Mr Ashford, make me 10 spinning wheels”. This was not the sort of challenge Walter wanted to take up for the second time, remembering with distaste a storeroom of wheels, at the end of the war. But Pamela persisted, emphatic that wool was the only wonder fibre, cool in summer and warm in winter. At agriculture and pastoral fairs, Pamela followed the country’s expert shearers spinning up the fleeces as they fell from their blades. She was persistent. Besides, why let that expertise go to waste? And so, once again Walter Ashford was in the right place at the right time.

Starting from where he left off, he saw the need to keep in touch with spinners, and by adapting, modifying, and streamlining factory procedures he produced the popular Ashford Traditional Spinning Wheel while still in the modest Rakaia premises. With little promotion, spinning groups mushroomed all over the country.

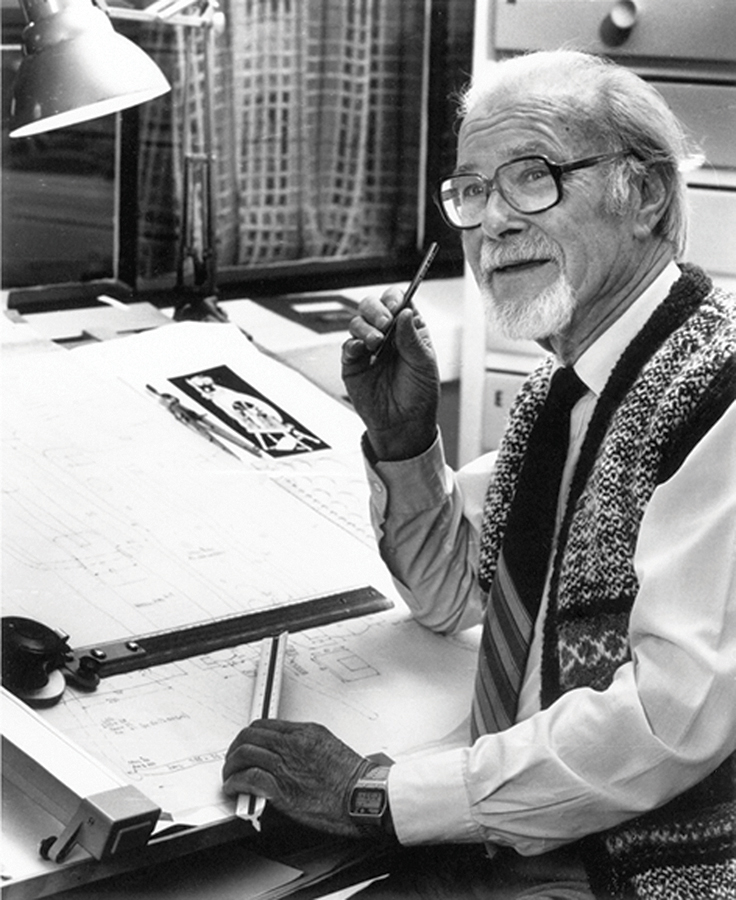

In 1986 Walter was awarded the Queen’s Service Medal, a fitting honour for a man who gave a lifetime’s dedication to crafts and his local community.

To view the Ashford Traditional spinning wheel timeline CLICK HERE.

Next generation

In 1972, Walter’s son Richard joined the business and exports around the world began in earnest. Richard travelled extensively to find new customers and conduct market research. Back in NZ Richard used this feedback to drive innovation and soon a range of spinning wheels, weaving looms, carding equipment and accessories followed, including electronic spinners and carders, folding and portable spinning wheels and weaving looms.

A larger factory was needed, and Richard designed the new Ashburton plant. Now, with plenty of space, machinery and skilled craftsmen, the manufacture of spinning wheels surged ahead. Richard also saw the need to provide customers with consumables to use with the equipment and ranges of fibre, yarns, books, dyes were developed. To ensure spinners and felters had access to the best quality fibre the company purchased a woollen mill in Milton. In control of the whole process – from sheep to consumer – the company could ensure the quality and offer a range of colours and blends.

Richard’s wife Elizabeth started publishing The Wheel magazine in 1987 as a way of promoting the crafts and connecting textile artists from around the world. The magazine featured projects from talented textile artists and revealed the joy, satisfaction, and peace that crafts bring to many. The 35th issue printed in 2023 featured the most popular projects, patterns, and articles from the previous 34 years. To help reduce the company’s carbon footprint in 2024 they moved to an online format. Now textile artists can access their craft content anytime and anywhere they have an internet connection.

(To register go to Ashford.co.nz/blog to be notified of all new articles, projects, pattern, and competitions direct to your inbox.)

In 2015, the business was passed on to James Ashford, the founder’s grandson and a former software engineer, and his husband David Lester, originally an accountant. Under their leadership, the brand’s best-loved products have continued to improve technologically to meet the needs of modern consumers.

From these small beginnings Ashford has now produced over 900,000 spinning wheels and weaving looms and are exporting to over forty countries.

Quality, reliability, and durability

The key to success has been Ashford’s devotion to quality, reliability, and durability. Only the best of materials are used. There is also a continual process of improvement and innovation in design, while retaining the aesthetic appeal of a graceful spinning wheel. As international spinning instructor Patsy Zawistoski says, “Spinners ask me: ‘What is your ‘go to’ wheel?’ An Ashford of course! For traveling and teaching I always use an Ashford wheel. I learned on my Ashford Traditional in 1981. Today I travel with my Ashford Joy; it packs easily, travels well, sets up in less than a minute, and carries its own bobbins. Now the Joy has an optional art yarn flyer with larger bobbins and a sliding yarn guide. It is the most versatile wheel I own, I teach everything on the Joy from cotton to cashmere, to thick, soft woollen yarn or highly textured bouclé.

Over the 30 plus years I have owned Ashford wheels I have appreciated how Richard and his team listen to their customers and users; making changes and improvements to their already great wheels. Kudos to the thought and quality that go into Ashford products! Whether it is spinning or weaving equipment. Yes, there are a number of good wheels on the market, but my most reliable and most used wheels are Ashford. Ashford is spinning wherever you are”.

Sustainable development

Since the beginning, the company’s philosophy is to respect nature and work ethically and sustainably. The solid wood products are made of Beech hardwood from Forestry Stewardship Council-approved mills.

The Ashford family take great pride in the knowledge that their wheels and looms enhance the lives of spinners and weavers around the world, especially where they are used to contribute to families’ wellbeing and livelihood.

In 2019 the Richard and Elizabeth Ashford Award was established to encourage and support textile artists around the world.

And of course, spinning and weaving are eco-friendly activities that reduce the dependence on non-renewable resources.

The company, founded in 1934 continues to this day as a family business. The third generation, James Ashford, and his husband, David Lester, is continuing the tradition of providing high quality, affordable products and ongoing excellent service and support.

Happy crafting.

National Radio NZ Country Life Interview